Controlling High Voltage Ramp

The high voltage* applied by your Cirris tester is a just one of the carefully controlled variables used to determine the dielectric withstanding voltage or the insulation resistance of your cable or harness assembly.

Insulation is designed to prevent the movement of electrons under force. If the force is too high or the insulation compromised, an avalanche of displaced electrons in the insulation will produce a destructive plasma seen as an arc or a spark.

The dielectric withstanding voltage (DWV) test puts a mechanical strain on the insulation by forcing the electrons and nuclei in the insulation from their normal positions. A DWV test failure is detected when a discharge, expressed as leakage current, exceeds a defined leakage current set point.

For the insulation resistance test, the high voltage is applied in order to force a measurable level of current through the high resistance presented by the insulation. Ohms law discovers the insulation resistance through voltage divided by current. An insulation resistance test failure is detected when the measured insulation resistance is found to be less than a defined insulation resistance set point.

When setting up a high voltage test, your specification for high voltage will tell you to use either an AC or DC source for the DWV test, the level of voltage, the dwell time, and sometimes the rate of application. It is this rate of application, also known as voltage ramp, that may cause concern.

Ramp Rate

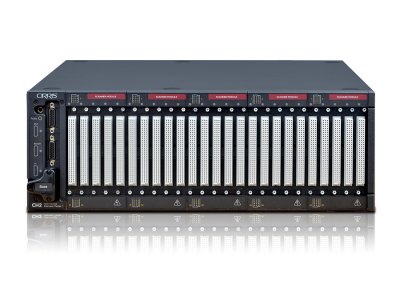

Of all Cirris tester models capable of high voltage DWV testing, only the CH2 provides a user-programmable ramp. In all other Cirris models, the ramp rate is automatic.

An automatic ramp rate leads to the question, what is the high voltage ramp rate when the rate is automatic? The answer is that the ramp rate is a variable and will be as fast as possible. The tester will determine the ramp rate automatically using an equation.

Part of the automatic ramp rate comes from the equation:

I = C * V / T

- I = the maximum current the high voltage supply can deliver (for the CH2 this is 2.5mA)

- C = the capacitance of the device under test + CH2 internal capacitance

- V = the dielectric withstand voltage set point

- T = the ramp time

The means that the equation to calculate ramp time would look like this:

T = C * V / I

For example, in a device under test with a net capacitance of 10nF at 1000V, and assuming a 500pF CH2 internal capacitance, the equation would look like this:

T = (10000e-12 + 500e-12) * 1000 / 2.5e-3

In this case, the ramp rate comes out to:

T = 4 mS

The final ramp rate will also include the time required by the software control systems that repeatedly elevates and measures the voltage, measures the current, and verifies the interlock status.

How does the automatic ramp rate comply with the specifications?

Several industry standards attempt to help clarify ramp rates.

SMC-020 Space and Missile Center Standard, Technical Requirement For Wiring Harness Space Vehicle

Paragraph 4.5.4.1 for high potential withstanding test at 60 Hz ac. says,

“The test potential shall be applied for at least 5 seconds at a rate of no less than 500 V per second until the desired potential is reached.”

This is difficult to interpret. If the ramp is 500 V / 1 second, then the ratio is 500/1 or simply 500. Then if you ramp to 500 V in 0.5 seconds your ratio is 500V/0.5 seconds – that is 500/0.5 or 1000 which is “no less than” 500. The specification avoids slow ramp rates in favor of one that is as fast as the automatic ramp on a Cirris tester.

MIL-STD-202G Test Method Standard Electronic and Electrical Component Parts Method 301 Dielectric Withstanding Voltage

Paragraph 3.4 Rate of application states,

“The test voltage shall be raised from zero to the specified value as uniformly as possible at a rate of approximately 500 volts (rms or dc) per second unless otherwise specified. At the option of the manufacturer, the test voltage may be applied instantaneously during in-plant quality conformance testing.”

The word “approximately” in MIL-STD 202 makes the ramp rate look more like a recommendation than a specification. Ultimately, the phrase “unless otherwise specified” leaves ramp rate up to the designer of the unit under test.

UL 2338 Section 38 Dielectric Voltage-Withstand Test

This standard states,

“The condition A test potential may be applied gradually until the full test potential is attained. For the Condition B, 1-s test, the full test potential shall be applied at the beginning of the test.”

The word “gradually” is not a tough specification to meet, but difficult to interpret.

IPC/WHMA-A-620AS with the Amendment 1 Space Applications Electronic Hardware Addendum to IPC/WHMA- A-620A Requirements

The AC Ramp Rate is not specified in this standard.

While the specifications do not accommodate the capacitance factor that draws current, regulation is arbitrary and too much time is spent in ramp.

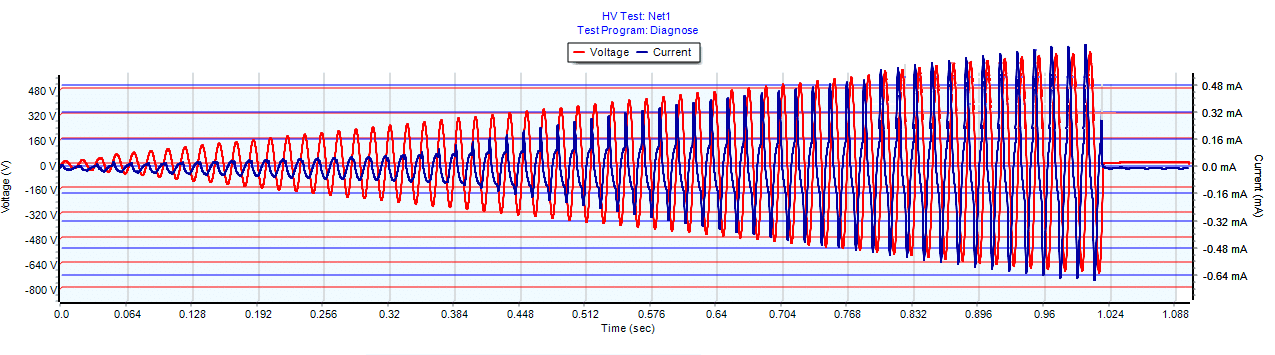

This can be further seen in the following example:

In ramping AC high voltage, you are elevating the voltage peak at each alternation of the sine wave by an amount equal to the ultimate voltage divided by the time divided by the frequency. If your AC voltage is 500 V RMS, your peak voltage is 707 V AC. At each alternation, the voltage peak would increase by (707/1)/60 or 11.8 V at 60 Hz. Regardless of the stated ramp rate, the voltage rises from zero to the peak in .017 seconds and moves from peak to peak in 0.34 seconds. Which ramp is meaningful, the peaks that increase over one second or the peak to peak ramp that occurs in 0.34 seconds?

Your specification may be written in a way that limits your instrument choices. In such cases, the Cirris CH2 meets your requirements for manual ramp rate setting. The CH2 even has an optional xHV power supply that provides extended AC voltage as well as a user-defined ramp down control. This manual ramp rate is not the only attractive feature of the CH2. The CH2 has automatic ramp rate as well.

When you are tasked to meet demanding throughput requirements, you will find that long and arbitrary manual ramp rates mean wasted time and lower output. The automatic ramp is the smart and safe way to maximize voltage application efficiency.

* 50 to 2000 VDC and 50 to 1500 VAC