4-Wire Kelvin Testing

If you have used an ohmmeter to make resistance measurements, you may have heard of the terms “2-wire measurement” and “4-wire Kelvin measurement.” This article explains how ohmmeters measure resistance, the differences between 2-wire and 4-wire resistance measurements, and the special considerations for each.

How do ohmmeters work?

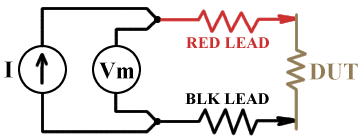

When using an ohmmeter to measure the resistance of a wire, the red meter lead is touched to each end of the wire and the black lead to the other end (figure 1). How does the meter measure resistance? What resistance is it really measuring? To understand how ohmmeters work, start with Ohm’s law:

Resistance = Voltage / Current (R = V/I)

To perform the measurement, the ohmmeter forces a known current through the wire, measures the voltage drop that develops, calculates the resistance using Ohm’s law, and displays the result. To do this, the ohmmeter must have a current source and voltmeter (see figure 1). Of key importance, is the point at which the current source and voltmeter connect.

Figure 1. Meters contain a current source (I) and a voltmeter (Vm).

Figure 2. A 2-wire measurement really measures the DUT resistance plus the meter lead resistance.

2-wire measurements

When making a 2-wire resistance measurement, the meter uses only two leads to connect to the device-under-test (DUT) as shown in Figure 2. This setup has the advantage of using just two wires to connect to the DUT, but the result is that the voltmeter measures the voltage drop across the DUT and the test leads.

4-wire measurements

Meters capable of performing 4-wire measurements use four leads (figure 3). Two leads connect to the current source (the Force+ or High and the Force- or Low), and two connect to the voltmeter (the Sense+ or High and the Sense- or Low). The Force High and the Sense High make up one 4-wire pair and the Force Low and Sense Low make up the second 4-wire pair (see figure 4). One of the main benefits of the 4-wire measurement method is that the resistance measurement is made between the points where the force and sense leads connect thereby eliminating the resistance of the leads from the measurement.

Figure 3. A 4-wire measurement. Notice the meter has four connections.

Figure 4. A 4-wire measurement gives you control of where the voltmeter connects.

You may not need 4-wire with a Cirris tester

Many continuity testers require 4-wire testing to accurately measure resistances under 1 ohm. However, Cirris testers can accurately measure resistance down to 0.1 ohm. One reason Cirris testers excel at this capability is because even during 2-wire measurements, the testers use the 4-wire measurement principle internally to eliminate extraneous internal resistance from measurements providing a consistent, near-zero resistance at the face of the test points connectors. This configuration is invisible to the user and the benefit it provides requires no action of the part of the user.

When determining whether to use 2-wire or 4-wire measurements in an application, don’t forget to consider all the tolerances and variances that are factors in resistances measurement (see Setting Practical Resistance Specs for more informant on the topic). Connecting the DUT directly to adapters on Signature series testers eliminates much of the fixturing resistance and variances that occur when using adapting cables.

Why not just subtract interface cable resistance?

Subtracting the fixturing resistance from resistance measurements is referred to as a subtracting a “tare value.” While the tare can be used to adjust measurements, it’s not as simple as it first appears. First the accuracy of the tester is reduced by the ratio of fixturing to DUT resistance. For example, a 0.1 ohm DUT measurement with 2 ohms of fixturing and a 2% tester accuracy has (2 + 0.1) ohms x 2% = 0.042 ohms of variation or 42% measurement error (adjusted measurement error = Tester measurement error x (fixture resistance + DUT actual resistance) / DUT actual resistance). In this example the threshold for a good cable would need to be adjusted to 0.1 x (100%- 42%) = 0.058 ohms.

There is a more serious concern when “taring out” the fixture resistance. Try measuring the resistance of a piece of wire with your VOM. You will find that the resistance varies depending on how hard you hold your test leads to the wire ends. This variation in resistance comes from the point of contact between the DUT and the fixturing. This resistance variation from measurement to measurement can add significantly to a learned resistance and will get worse as the mating connectors wear. The result of this variation could be that resistance thresholds are set too high and defective cables are allowed to pass.

How does 4-wire testing benefit you?

- Properly configured, 4-wire measurements significantly reduces or eliminates the resistance of fixturing from the measurement. If fixturing resistance is a significant part of the total resistance, then accuracy will be greatly improved.

- It allows lower resistance measurements than 2-wire testing. Cirris high voltage testers use higher current when performing 4-wire Kelvin tests providing greater accuracy when measuring very low resistances down to 1 mΩ (0.001 ohm). Cirris low voltage testers can measure down to 5 mΩ (0.005 ohm) but can still resolve to 1 mΩ.

- If 4-wire connections are made on the DUT, not just in the connector that mates to the DUT, all the fixturing resistance can be eliminated. However, this extra effort may not be necessary or feasible.

What does 4-wire testing cost you?

- Complexity in fixturing – more wiring, increased design and built effort, and more maintenance over time.

- Twice the number of test points are required for 4-wire measurements.

- Slower testing speed.

What you need to know before you can build a 4-wire test fixture

Proper “force” and “sense” points must be combined into 4-wire pairs. Not just any 2-points can be paired to create 4-wire fixturing. There are simple rules that tell you what points need to be paired. Don’t build it wrong! Check the 4-wire instructions for your tester in the corresponding user manual.

The loop resistance (the resistance from the tester through a source/sense 4-wire pair) must be less than 10 ohms.

Which Cirris Tester should I use?

| Tester | Max Current | Accuracy | Notes |

| CH2 | 2 Amps | +/- 0.001 Ω, +/- 2% | 1-point 4-wire pair offset (points 1 & 2, 3 & 4 etc.) |

| Easy-Touch Pro & 4250 | 1 Amp | +/- 0.001 Ω, +/- 2% | Pairing of points is programmable within constraints |

| 8100 & CR | 6 mA | +/- 0.005 Ω, +/- 2% | CR 32-point offset; 8100 1-point or 32-point offset |

| 4200 | 6 mA | +/- 0.005 Ω, +/- 2% | Pairing of points is programmable within constraints |