|

How Long Will My Adapter Last?

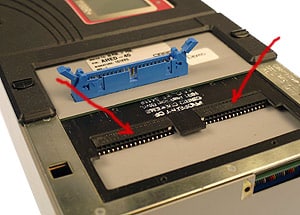

We regularly receive calls asking about the life expectancy of Cirris test adapters. This is a very difficult question to answer because there are so many variables to consider. Here we’ll attempt to shed some light on those variables, provide you with useful information, and offer some ideas and suggestions to help you get maximum life out of your mating test adapters.

Cirris doesn’t “make” connectors, we buy them like everyone else!

A regular misconception is that, because Cirris sells adapter cards we make connectors. We don’t, we buy them from connector manufacturers like everyone else. We want our adapters to last as long as possible so we always look for the highest quality, longest life connectors that we can find. We do extensive life-cycle testing to assure that you get as many cycles as possible out of your Cirris adapters.

Manufacturers Specs:

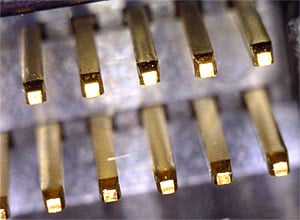

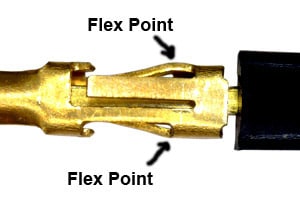

Connector manufacturer’s data sheets generally include technical specs on electrical properties such as current and voltage ratings, contact resistance and mating cycles. The “mating cycle” spec tells you how many mating cycles you can expect for the connector to maintain its rated “contact resistance” value. This will vary depending on the type of metal used (tin, copper, brass, gold, etc), the type of plating (usually gold) the thickness of the plating, and other factors. Most manufacturers will offer several grades of connectors with differing mating cycle ratings. Cheaper connectors (tin plating) may be rated for as few as 10 to 50 cycles, while the more expensive connectors (thicker gold plating) are generally rated for 500 cycles.

500 mating cycles! Why that’s barely a day’s worth of testing!

It’s true, that seems like a very small number of mating cycles for a test adapter , but remember, the manufacturer’s spec is for how many mating cycles you can expect at the specified contact resistance rating.

(In most cases, customers get many times more mating cycles out of our adapters.) Below are several considerations that go into determining how many cycles you might get.

Connection Resistance Test Threshold:

Electrical connectors, like the tires on your car, wear out with use. Obviously, the lower your pass/fail threshold for connection resistance, the fewer number of mating cycles you’ll get before you start to see high resistance failures. For example: a 25 pin D-Sub adapter rated for 500 cycles at less than 25m ohms might give you 1000 tests with a .1 ohms threshold. If you increase the test threshold to .5 ohms you might get several thousand tests. At 1 ohms that could increase to 5000. Go up to 5 ohms and you may get 10,000. (these numbers aren’t a guarantee, only to give an example) |